Are you seeking information on Pre Engineered Metal Buildings? Northland Steel Buildings™ are contractor-friendly metal buildings because they are designed and manufactured from a contractor’s perspective. Long before we became a manufacturer, we were a metal building contractor. We knew there had to be a better way to engineer and erect metal buildings. To that end, we partnered with two state-of-the-art plants that combined design features from the construction trades with streamlined manufacturing techniques. The discipline of IAS AC472 accreditation (U.S.) and CSA-A660 (Canada) certified quality is evident from start to finish. The end result is the strongest, most efficient and most corrosive-resistant pre-engineered metal-buildings on the market today. Northland Steel Buildings™ are designed for the harsh northern climate and set the industry’s benchmark for quality.

We make it possible for builders to provide competitive pricing, fast construction and on-time completion by delivering complete building systems. We design and manufacture rigid frame clear span buildings of all sizes. Our projects range from manufacturing plants, commercial buildings and warehouses, to schools, churches, and recreational facilities, to airplane hangars, climate-controlled facilities, and other multi-use structures. No building is too large or too complex. Plus, every Northland metal building is built on a foundation of technical knowledge that has become our trademark.

Multi-Station Paint Line

When manufacturing pre-engineered metal buildings, the most recent plant expansion and improvement project is a state-of-the-art multi-station paint line.

The line consists of a large track system that transports steel through the Shot Blaster before sending it through the Finishing Systems paint booth. Paint is applied using an electro-static process. Once painted, the steel travels through the cure oven, providing a long-lasting, high quality finish.

This energy-efficient, environmentally-friendly process utilizes filtering and booth containment processes, improves product quality, and reduces painting and drying time.

Metal Building Framing Systems to Fill Every Building Requirement

As a leading Steel Building manufacturer serving Rhode Island (RI), Connecticut (CT), Massachusetts (MA), New Hampshire (NH), Vermont (VT), and Maine (ME), Northland Steel Buildings specializes in providing top-quality metal building framing systems tailored to the unique requirements of our customers.

Our metal building framing systems are meticulously crafted, typically featuring rigid frames constructed from robust bar or plate flanges and tapered webs. These components form the primary framing system, which serves as the fundamental support structure of the building.

When fully assembled, the metal building frames seamlessly unite to create a cohesive and resilient unit. This primary framing system for pre-engineered metal buildings plays a crucial role in transferring the structure's weight, or "load," to the foundation, ensuring the stability and durability of the entire building.

At Northland Steel Buildings, we understand the importance of delivering exceptional quality and performance. That's why our steel building framing systems are engineered to withstand the demands of various applications, from commercial and industrial buildings to agricultural and residential developments.

With our expertise and dedication to excellence, Northland Steel Buildings is your trusted partner for high-quality steel building solutions across Rhode Island, Connecticut, Massachusetts, New Hampshire, Vermont, and Maine. Experience the difference with Northland Steel Buildings – your premier Steel Building Manufacturer in the New England region.

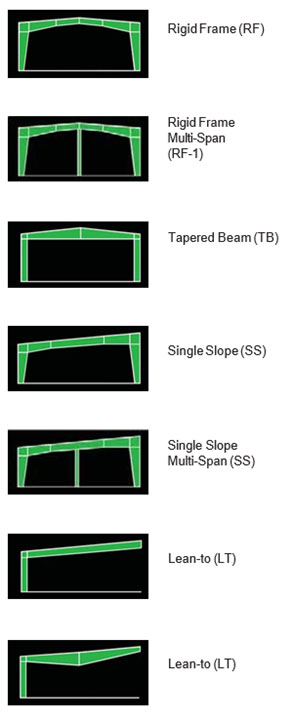

The strength and durability of All-Steel construction, Northland Steel Buildings™ give you greater design options. We can provide you with gable roofs, single-slopes, clear spans, multi-spans, and other rigid frame designs to meet your needs.

When choosing one of Northland’s pre-engineered metal building frames, you receive:

-

Great appearance. Design and size flexibility.

-

Efficient design capabilities. Economical start-up cost.

-

Fast construction.

-

Permanence with non-combustible materials.

-

Load requirements designed to fit your needs.

-

A finished look, with all structural steel, shop-coated with gray oxide primer.

Standard frame profiles include:

-

Rigid Frame (RF) Tapered Beam (TB) Single Slope (SS)

-

Lean-to (LT)

Extended Bays Up To 50 Feet

We offer Extended Bays for buildings requiring large areas of open floor space and a minimum number of columns, providing a clean, uncluttered interior. Also, open web joists are designed to function as an integral part of the pre-engineered system. Joists are suitable for supporting floors, roof decks, and standing seam roofs, and generally, joists are more economical when bay sizes are wider than 30', or when roof loads are excessive.

Extended bays can integrate with other Northland Building System products and are adaptable to virtually any type of roof and wall system.

Features:

-

Bay Spacing up to 50' Fast

-

Economical Erection

-

Optimize Column Locations and Bay Spacing

-

Traditional Purlin Compatible

-

Available with Standing Seam Roof Panels

-

Use with B-Deck, Built-Up and Single Ply, or Standing Seam Roof

-

Design Flexibility

Benefits:

-

IAS AC472 Accreditation (U.S.)

-

CSA-A660 Certification (Canada)

-

Easy Erection

-

Cost Savings

-

Bolts to Main Frame

-

Spans up to 50'

Environmentally Friendly “COOL ROOF” Panels

Northland Cool-Color roof panels are manufactured with reflective Trinar® 70% paint. Durable Trinar® on Northland Cool ColorTM panels provides reflectance and emissivity to meet ENERGY STAR® requirements.

Authorized Northland Independent Builders provide their customers the benefits of lower energy costs, increased roof life expectancies, superior roof color choices, the comfort of our 30-year limited warranty, and a cooler, cleaner, "Greener" environment for all of us.

Colors that meet Cool Roof

solar reflectance requirements are:

Low Slope (less then 2:12):

- Arctic White

High Slope (greater than 2:12):

- Arctic White

- Parchment

- Buckskin Tan

- Antique Red

- Ash Gray

- Light Stone

Standard frame profiles include:

-

Rigid Frame (RF)

-

Tapered Beam (TB)

-

Single Slope (SS)

-

Lean-to (LT)

Features:

- Bay Spacing up to 50' Fast, Economical Erection

- Optimize Column Locations and Bay Spacing Traditional

Purlin Compatible - Available with Standing Seam Roof Panels

- Use with B-Deck, Built-Up and Single Ply, or Standing Seam Roof Design Flexibility

Benefits:

- IAS AC472 Accreditation (U.S.)

- CSA-A660 Certification (Canada)

- Easy Erection

- Cost Savings

- Bolts to Main Frame

- Spans up to 50

Trinar 40-Year Limited Warranty!

Northland Steel Buildings™ are designed for the harsh northern climate.

All Northland panels are produced in Premium Trinar® long-life fluoropolymer finishes, and carry our

40-year color warranty. We also produce our own matching gutter and down spout systems. At Northland, it’s the details that make the difference, with quality finished products creating greater owner appeal.

• UV Resistant

• Heat Resistant

• Chmical Resistant

• Unparalleled Gloss and Color Retention

• Highest Quality Ceramic

• Resists Chalking, Fading, Chipping, and Cracking

• Resists Stains